Product Description

Coresun Drive SC9 slewing drive gear motor worm gear for 18-32 square meter solar tracker system.

Slewing drive motor for single and dual axis solar plant,PV and CSP system.

solar tracker generator motor is customized can can choose 12V,24V,48V,220V380V motor drive.

|

Model |

SC9 |

IP |

IP65 |

|

Brand |

Coresun Drive |

Available Load Weight |

500-800kg |

|

IP Class |

IP65 |

Output Torque |

805.3N.m |

|

Tilting Moment |

33.9kN.m |

Holding Torque |

38.7kN.m |

|

Mounting Bolts |

M16 |

Electrial Motor |

24VDC |

|

Gear Ratio |

61:1 |

Efficiency |

40% |

CHINAMFG Drive Equipment HangZhou Co., Ltd.

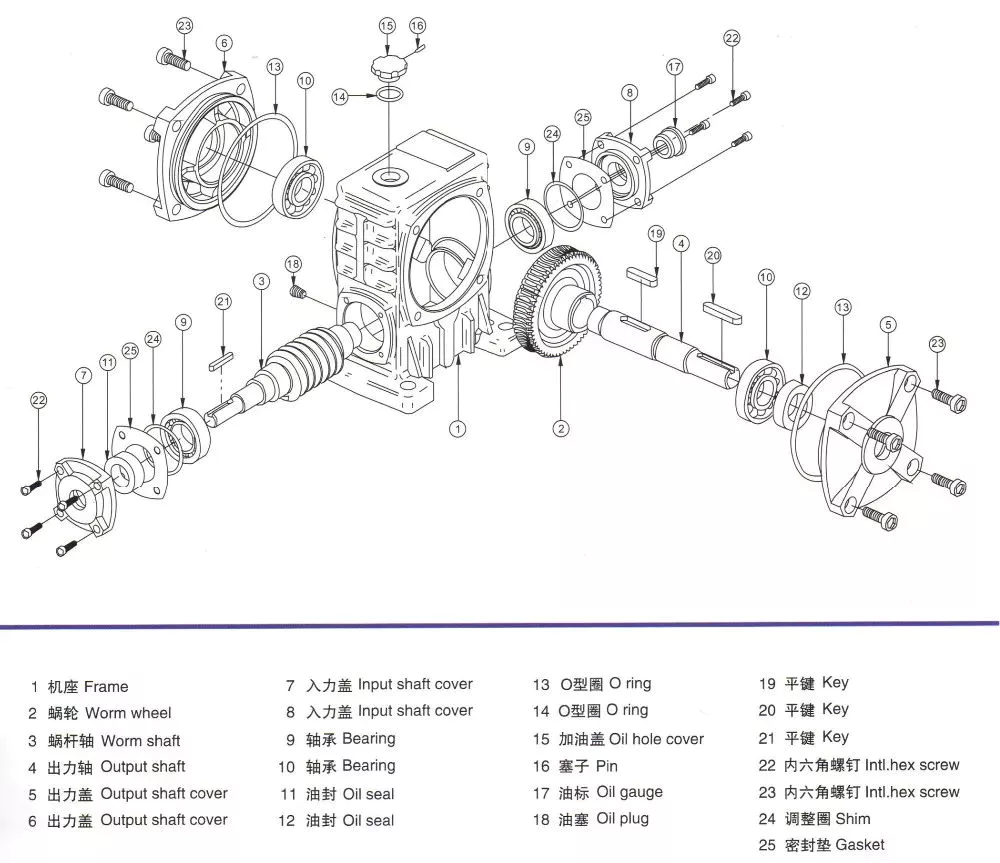

Rotary drive is a full cycle rotary reduction transmission mechanism that integrates a driving power source. It uses a rotary bearing as the driving follower and mechanism attachment. By attaching an active component, driving source, and cover to 1 of the inner and outer rings of the rotary bearing, the other ring is used as both the driving follower and the connecting base of the driven working component. This takes advantage of the characteristic that the rotary bearing itself is a full cycle rotary connector, Efficient configuration of the driving power source and main transmission components makes it a universal reduction transmission mechanism that integrates rotation, deceleration, and driving functions, while also having a simple structure and convenient manufacturing and maintenance.

Slew Drive are widely used in PV,CPV,STP solar tracking systems and construction applications including truck cranes, manlifts, turntables, port machinery, modular vehicles, small wind power systems and satellite communications.

1.Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2.We devote ourselves to the R&D of customized slewing bearing with high precision,special purpose and requirements.

3.With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4.Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality.The company has complete testing equipment and advanced testing method.

5.Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

Coresun Drive Slewing Drive Motor Production Photo and Application

CHINAMFG Drive processes the metallography detection to check the material and organization structure of worm shaft,slewing gear and casting housing.

CHINAMFG Drive slewing drive gear motor with 24VDC motor is certificated by CE

CONTACT US

CoreSun is your reliable supplier, even more your sincere partner! We are looking CHINAMFG to cooperating with you!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Holding Torque: | 38.7kn.M |

|---|---|

| Tilting Moment: | 33.9kn.M |

| Output Torque: | 805.2n.M |

| Solar Tracker: | Single and Dual Axis |

| Slewing Drive: | Worm Gear |

| Keyword: | Slew Worm Gear Drive |

| Customization: |

Available

| Customized Request |

|---|

What are the environmental considerations in the manufacturing and disposal of gear drives?

Manufacturing and disposal of gear drives have environmental implications that should be taken into account. Here’s a detailed explanation of the environmental considerations associated with these processes:

Manufacturing:

-

Raw Material Extraction:

– The extraction of raw materials, such as metal ores and petroleum-based products, for gear drive manufacturing can have environmental impacts.

– Mining activities can cause habitat destruction, soil erosion, and water pollution.

– The extraction and processing of petroleum-based products contribute to greenhouse gas emissions and can lead to oil spills and other environmental disasters.

-

Energy Consumption:

– The manufacturing process of gear drives typically requires significant energy consumption.

– Energy-intensive processes, such as machining, casting, forging, and heat treatment, contribute to greenhouse gas emissions and air pollution.

– Manufacturers should strive to optimize energy efficiency, use renewable energy sources, and implement energy management practices to minimize the environmental impact.

-

Waste Generation:

– Gear drive manufacturing can generate various types of waste, including metal shavings, coolant and lubricant waste, and packaging materials.

– Improper disposal of these wastes can lead to soil and water contamination.

– Manufacturers should implement waste management practices, such as recycling, reusing, or properly treating and disposing of waste materials, to minimize their environmental impact.

-

Chemical Usage:

– Chemicals, such as lubricants, cleaning agents, and coatings, are often used in the manufacturing process of gear drives.

– Improper handling, storage, or disposal of these chemicals can be harmful to the environment and human health.

– Manufacturers should adhere to proper chemical management practices, including the use of environmentally friendly alternatives, safe storage, and responsible disposal.

Disposal:

-

End-of-Life Management:

– Gear drives eventually reach the end of their useful life and require proper disposal or recycling.

– Improper disposal can lead to the accumulation of gear drives in landfills, resulting in the wastage of valuable materials and potential environmental contamination.

– Manufacturers should encourage the return or collection of used gear drives for recycling or proper disposal.

-

Recycling:

– Recycling gear drives helps recover valuable materials and reduces the demand for new raw materials.

– However, gear drives can be complex assemblies with various materials, making recycling challenging.

– Proper dismantling and separation of materials are necessary for effective recycling.

– Manufacturers should explore design strategies that facilitate disassembly and recycling, such as using recyclable materials and minimizing the use of hazardous substances.

-

E-Waste Regulations:

– In some regions, gear drives may fall under electronic waste (e-waste) regulations due to their electronic components.

– Manufacturers should comply with applicable e-waste regulations, which often require responsible disposal and recycling of electronic components.

– This ensures that hazardous substances are managed properly and valuable materials are recovered.

By considering these environmental aspects in the manufacturing and disposal of gear drives, manufacturers can strive to minimize the environmental impact, promote sustainability, and meet regulatory requirements.

What is the expected lifespan of a typical gear drive?

The expected lifespan of a typical gear drive can vary depending on various factors. Here’s a detailed explanation:

1. Design and Manufacturing Quality:

– The design and manufacturing quality of the gear drive significantly impact its lifespan.

– Well-designed gear drives with precise manufacturing processes tend to have longer lifespans.

2. Load and Operating Conditions:

– The magnitude and nature of the load applied to the gear drive, as well as the operating conditions, affect its lifespan.

– Heavy loads, high speeds, and harsh operating environments can potentially reduce the gear drive’s lifespan.

3. Lubrication and Maintenance:

– Proper lubrication and regular maintenance are crucial for extending the lifespan of a gear drive.

– Adequate lubrication reduces friction and wear, while timely maintenance allows for the detection and resolution of potential issues.

4. Material Selection:

– The choice of materials used in the gear drive construction impacts its lifespan.

– High-quality and durable materials, such as hardened alloy steels, can enhance the gear drive’s longevity.

5. Operating Time and Duty Cycle:

– The total operating time and duty cycle of the gear drive influence its lifespan.

– Gear drives subjected to continuous or frequent operation may experience more wear and fatigue, potentially shortening their lifespan.

6. Maintenance Practices:

– The effectiveness of maintenance practices, including inspections, lubricant replacement, and component replacements, can significantly impact the gear drive’s lifespan.

– Regular and proactive maintenance can help identify and address potential issues before they lead to catastrophic failure.

7. Application-Specific Factors:

– The specific application requirements and environmental factors unique to each gear drive installation can influence its lifespan.

– Factors such as shock loads, temperature variations, and exposure to contaminants can affect the gear drive’s durability.

Considering these factors, the expected lifespan of a typical gear drive can range from several years to several decades. In industrial applications, gear drives are often designed with an intended lifespan of 10 to 20 years under normal operating conditions and proper maintenance practices. However, it’s important to note that unexpected conditions, inadequate maintenance, or excessive wear can shorten the actual lifespan of a gear drive.

How do you maintain and lubricate gear drives?

Maintaining and lubricating gear drives properly is essential for their smooth operation, longevity, and prevention of premature failure. Here’s a detailed explanation of the maintenance and lubrication practices for gear drives:

1. Inspection and Cleaning:

– Regularly inspect the gear drive for any signs of wear, damage, misalignment, or contamination.

– Clean the gear drive components, including gears, shafts, bearings, and housings, to remove debris, dirt, and old lubricant.

2. Lubrication:

– Select an appropriate lubricant based on the gear drive design, load capacity, operating speed, and ambient conditions.

– Follow the manufacturer’s recommendations for lubricant type, viscosity, and change intervals.

– Apply the lubricant evenly to the gear teeth, shafts, and bearings to ensure proper lubrication and minimize friction.

– Monitor the lubricant level and replenish or change it as needed to maintain optimal lubrication conditions.

3. Temperature Monitoring:

– Monitor the operating temperature of the gear drive using temperature sensors or thermal imaging devices.

– Excessive heat can indicate inadequate lubrication, overloading, misalignment, or other issues that need attention.

– Take corrective measures if the temperature exceeds the recommended range to prevent damage and ensure proper lubrication.

4. Alignment and Adjustment:

– Check and correct gear drive alignment regularly to ensure proper meshing and minimize wear.

– Adjust the gear drive components, such as bearings and shafts, as per the manufacturer’s specifications.

– Misalignment can lead to increased friction, premature wear, and reduced gear drive efficiency.

5. Vibration Analysis:

– Monitor the gear drive for abnormal vibrations using vibration analysis techniques.

– Excessive vibrations can indicate issues like gear tooth damage, bearing failure, or misalignment.

– Address any abnormal vibrations promptly to prevent further damage and maintain smooth operation.

6. Regular Maintenance Schedule:

– Establish a maintenance schedule and adhere to it to ensure consistent and timely gear drive maintenance.

– Include tasks such as lubricant checks and changes, inspections, alignments, and other maintenance activities.

– Keep records of maintenance activities, including lubricant changes, inspections, and repairs, for future reference.

By following these maintenance and lubrication practices, gear drives can operate efficiently, minimize wear and tear, and have a longer service life. It is important to refer to the manufacturer’s guidelines and consult with experts when performing maintenance on specific gear drive systems to ensure proper care and optimal performance.

editor by Dream 2024-04-29