Product Description

Company Profile

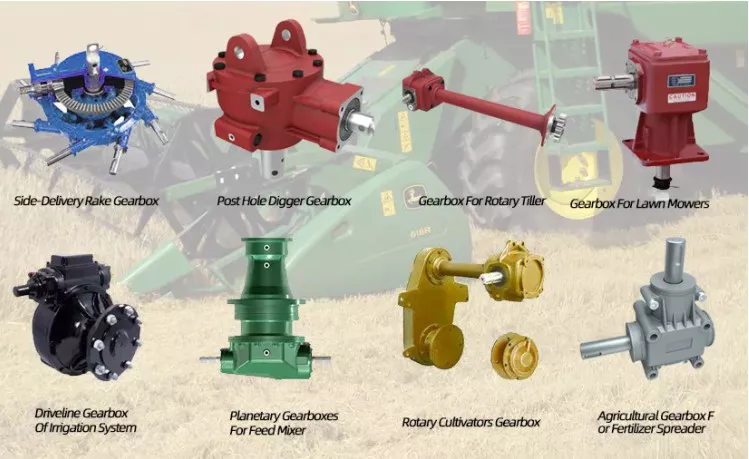

We CHINAMFG is a OEM factory, accpet customerized. Most of our products are customerzation.The product include gear housing/boxes/reducers, Iron casting products, Aluminum products. Such as auto parts, agriculture parts, and other industrial parts.

We have the most advanced testing facilities, such as spectral analyzer for rubber material chemical composition test, tensile strength testing machine, impact value tester and hardness meter, magnetic particle testing machine, sandblasting machine and heat treatment equipment. Besides, there are numerous advanced equipment in the precision machining workshop: have 23 sets CNC lathes, 10sets vertical CNC boring and milling center and 1 horizontal boring and milling center imported from Korea, 2 general milling machine, and 2 general lathes, 1 grinder, 10sets drilling and tap machines, 2 half automatic saw, and 1 Coordinate Measuring Machine (CMM), 1 Projector and 1 machining surface quality testing machine and 1 Mahr altitude instrument. Our product’s tolerance can be controlled under 0.01mm. The testing machine’s accuracy is within 0.005mm. ISO9000 has been executed.

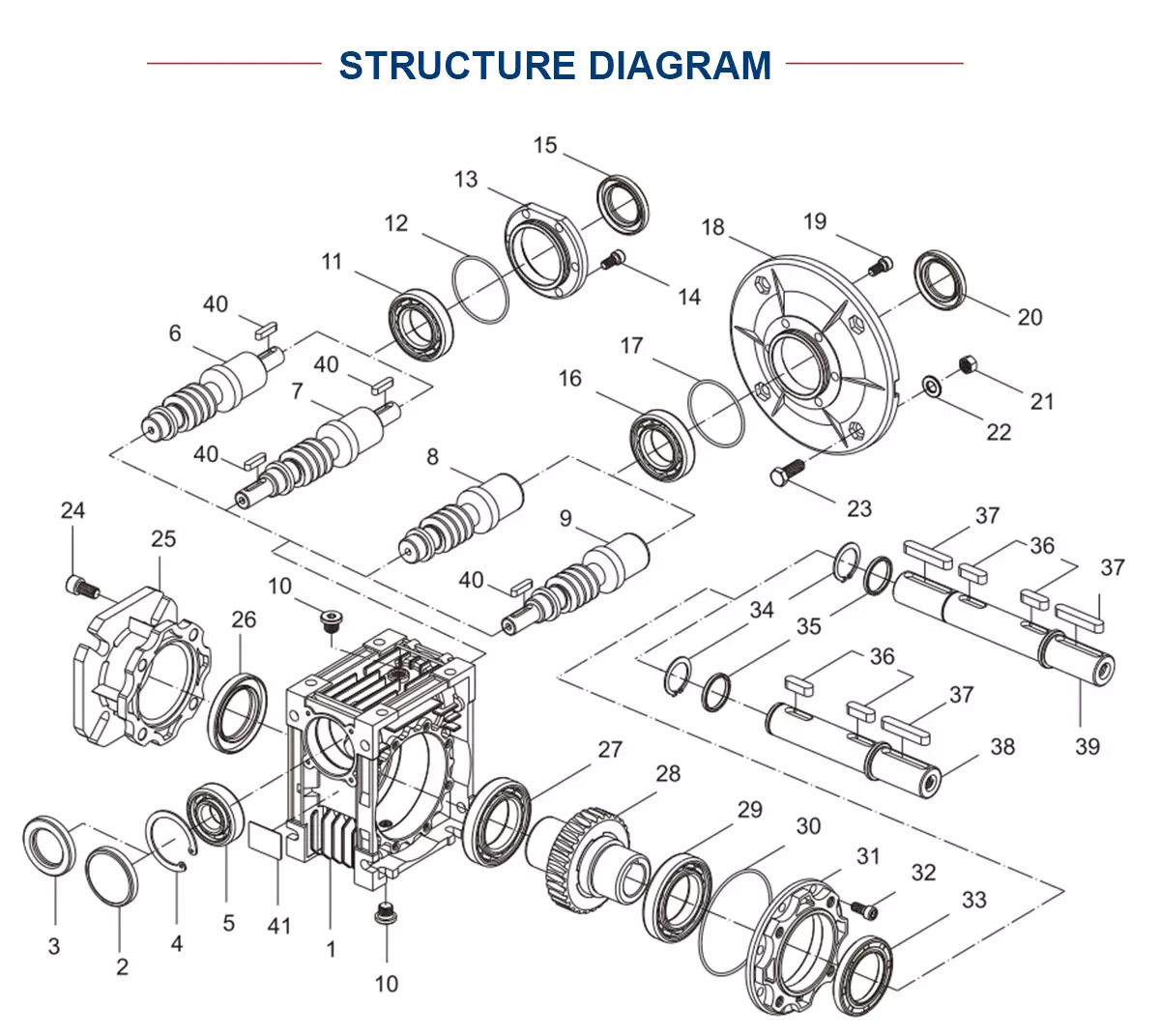

Product Parameters

| Maximum torque: | 20,000NM |

| Maximum output speed: | <1200rpm |

| Maximum input speed: | <2500rpm |

| Ratio: | 3:1 up to 4:1 |

| Output type: | square shaft hex shaft flange |

Our Advantages

1. 20 years of experience in manufacturing and exporting

2. OEM and custom-made service

3. All kinds of castings can be manufactured according to the drawings, samples or specific industry standard

4. Strong engineering team makes high quatliy

5. The coordinated service(casting, machining and surface treatment) make lower price if possible

6. Advanced-level equipments

7. Full material testing process and quatliy control system

8. Quality assurance and delivery on time

About CHINAMFG Industrial

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Samples: |

US$ 3000/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do gear drives differ in precision machinery compared to heavy machinery?

Gear drives can exhibit differences in their characteristics and applications when used in precision machinery compared to heavy machinery. Here’s a detailed explanation:

1. Gear Design and Tooth Accuracy:

– In precision machinery, such as precision instruments or high-precision machine tools, gear drives often require higher gear design and tooth accuracy.

– The gear teeth in precision machinery gear drives are meticulously manufactured to strict tolerances, ensuring smooth and precise motion transmission.

– The gear tooth profiles may be designed with finer pitches and optimized tooth forms to achieve the desired accuracy and minimize backlash.

2. Load Capacity and Torque:

– Heavy machinery, such as construction equipment or industrial machinery, typically requires gear drives with higher load capacity and torque-handling capabilities.

– These gear drives are designed to withstand larger forces and transmit higher levels of torque without deformation or failure.

– Heavy machinery gear drives may have larger gear sizes, wider gear teeth, and additional structural reinforcements to handle the demanding operating conditions.

3. Operating Speed and Efficiency:

– Precision machinery often operates at higher speeds and requires gear drives with low noise, vibration, and backlash.

– Gear drives in precision machinery are designed for high efficiency and smooth operation to minimize any adverse effects on precision tasks.

– Heavy machinery gear drives prioritize robustness and load-carrying capacity, and they may sacrifice some operating speed and efficiency for increased durability.

4. Lubrication and Cooling:

– Lubrication and cooling requirements can vary between precision machinery and heavy machinery gear drives.

– Precision machinery gear drives may have specific lubrication systems to ensure precise lubricant application and minimize any potential contamination or wear.

– Heavy machinery gear drives may require robust lubrication systems capable of handling higher temperatures, heavier loads, and harsh operating environments.

5. Size and Weight:

– Gear drives in precision machinery often prioritize compact size and lightweight design to fit within limited space and reduce inertia.

– Heavy machinery gear drives may be larger and heavier due to the need for increased load-carrying capacity and structural strength.

6. Cost Considerations:

– Precision machinery gear drives may involve higher manufacturing costs due to the need for tighter tolerances, precision machining, and specialized materials.

– Heavy machinery gear drives may focus on cost optimization while ensuring sufficient strength and durability for the intended applications.

These differences highlight how gear drives can be tailored to meet the specific requirements of precision machinery and heavy machinery. Whether it’s achieving high precision and smooth operation in precision machinery or prioritizing load capacity and durability in heavy machinery, gear drives play a crucial role in enabling efficient and reliable motion transmission in a wide range of applications.

How do environmental factors affect the performance of gear drives?

Environmental factors play a significant role in influencing the performance and lifespan of gear drives. Here’s a detailed explanation of how different environmental factors can affect gear drive performance:

1. Temperature:

– Extreme temperatures can impact the lubrication properties of the gear drive, affecting its efficiency and lifespan.

– High temperatures can cause lubricants to break down, leading to increased friction, accelerated wear, and potential damage to gears and bearings.

– Low temperatures can cause lubricants to thicken, reducing their ability to flow and properly lubricate the gear drive components.

2. Moisture and Humidity:

– Moisture and humidity can lead to corrosion and rust formation on gear surfaces and other metal components.

– Corrosion can cause pitting, erosion, and accelerated wear on gear teeth, reducing their performance and lifespan.

– Moisture can also contaminate lubricants, reducing their effectiveness and promoting additional wear and damage.

3. Dust and Contaminants:

– Dust, dirt, and other contaminants present in the environment can enter the gear drive system, affecting its performance.

– Contaminants can interfere with proper gear meshing, increase friction, and cause abrasive wear on gear teeth.

– Regular maintenance and proper sealing of gear drive enclosures can help minimize the ingress of contaminants.

4. Shock and Vibration:

– High levels of shock and vibration in the operating environment can affect gear drive performance and reliability.

– Excessive shock loads can cause gear tooth breakage or bending, leading to immediate failure or accelerated wear.

– Vibrations can result in misalignment, increased friction, and premature wear on gear teeth, bearings, and other components.

5. Load and Torque Variations:

– Variances in load and torque requirements can impact the gear drive’s performance and durability.

– Frequent and significant load changes can lead to increased wear and fatigue on gear teeth and other components.

– Proper gear drive selection, considering the anticipated load and torque variations, is crucial for optimal performance.

6. Acoustic and EMI Interference:

– Acoustic and electromagnetic interference from external sources can affect gear drive performance.

– Excessive noise or vibrations from nearby equipment can impact gear drive operation and increase the risk of damage.

– Electromagnetic interference (EMI) can disrupt electronic components and control systems associated with gear drives.

Considering these environmental factors and taking appropriate measures to mitigate their impact can help maintain the performance, reliability, and lifespan of gear drives. This includes selecting suitable lubricants, implementing proper sealing and protection, performing regular maintenance, and considering environmental conditions when designing and installing gear drive systems.

What are the different types of gear drives available?

There are several types of gear drives available, each suited for specific applications and requirements. Here’s a detailed explanation of some common types of gear drives:

1. Spur Gear Drive:

– Spur gear drives are the simplest and most common type of gear drives.

– They consist of cylindrical gears with straight teeth that are parallel to the gear axis.

– Spur gears provide high efficiency and are suitable for applications with low to moderate speeds and torque.

2. Helical Gear Drive:

– Helical gear drives have angled teeth that are inclined to the gear axis.

– The helical teeth allow for smooth and quiet operation, as they gradually engage and disengage.

– Helical gear drives can handle higher loads and speeds compared to spur gears and are commonly used in automotive transmissions and industrial machinery.

3. Bevel Gear Drive:

– Bevel gear drives consist of gears with conical-shaped teeth.

– They are used when the input and output shafts are not parallel but intersecting at an angle.

– Bevel gear drives are commonly found in applications such as differential gears in vehicles and power transmission systems for right-angle drives.

4. Worm Gear Drive:

– Worm gear drives consist of a threaded gear (worm) and a mating gear (worm wheel).

– They provide high gear ratios and are used when large speed reductions are required.

– Worm gear drives offer self-locking characteristics, meaning they can hold the load in position without the need for additional braking mechanisms.

5. Planetary Gear Drive:

– Planetary gear drives consist of multiple gears arranged in a planetary system.

– They offer high torque capacity, compact size, and versatility in speed and torque combinations.

– Planetary gear drives are commonly used in robotics, automotive transmissions, and industrial machinery.

6. Rack and Pinion Drive:

– Rack and pinion drives convert rotational motion into linear motion.

– They consist of a straight toothed rack (a flat gear) and a pinion (a gear with a small diameter).

– Rack and pinion drives are commonly used in applications such as steering systems, CNC machines, and linear actuators.

These are just a few examples of the different types of gear drives available. Each type has its advantages and is suitable for specific applications based on factors such as load capacity, speed requirements, space limitations, and desired gear ratios.

editor by Dream 2024-05-15